VOTE FOR THE BEST SOLUTION TO A RESIGNED PROBLEM WITH A FOCUS ON THE SAFETY AND INTEGRITY OF PEOPLE!

Check the 10 finalist projects below. You need to see all the submissions before being able to vote.

Equipo Encartuchada

Improvement of product movement with a vacuum crane system:

This project proposes to implement vacuum cranes in 4 production lines, making the process more efficient and ergonomic, reducing the physical effort of our collaborators.

Team Members:

Luiz Felipe da Silva, Maycon Marcelo de Fonseca, Alexandre Muhlmann Alves.

US Atlantic Nickel

Installation of tank and external pipe to refuel UMBs remotely

This project proposes the use external with recognition sensors in the refueling process, avoiding the need to have personnel working at height and reducing the risk when refueling UBMs.

Team members:

Antonio Carlos Batista da Silva, George Bomfin Silva, Bruno Ferreira da Silva.

US CSN

Implement a system to improve communication between operators and job site assistants

This project identified the lack of communication at the site as a resigned problem and proposes the use of electronic communication systems to pass all the information effectively, reducing misunderstandings and operating times between operators and job site assistants.

Team members:

Alexsander Valter Siqueira de Souza, Gabriel Dias Delfino, Andre Chaves Maciel.

US Sossego

Installation of pulley for handling hoses:

When handling hoses, collaborators usually require a lot of physical strength. This being their resigned problem, the team proposes the use of a pulley that can make it easier to lift the hose and reduce physical effort.

Team members:

Francisco Dias de Oliveira Filho + 36 members.

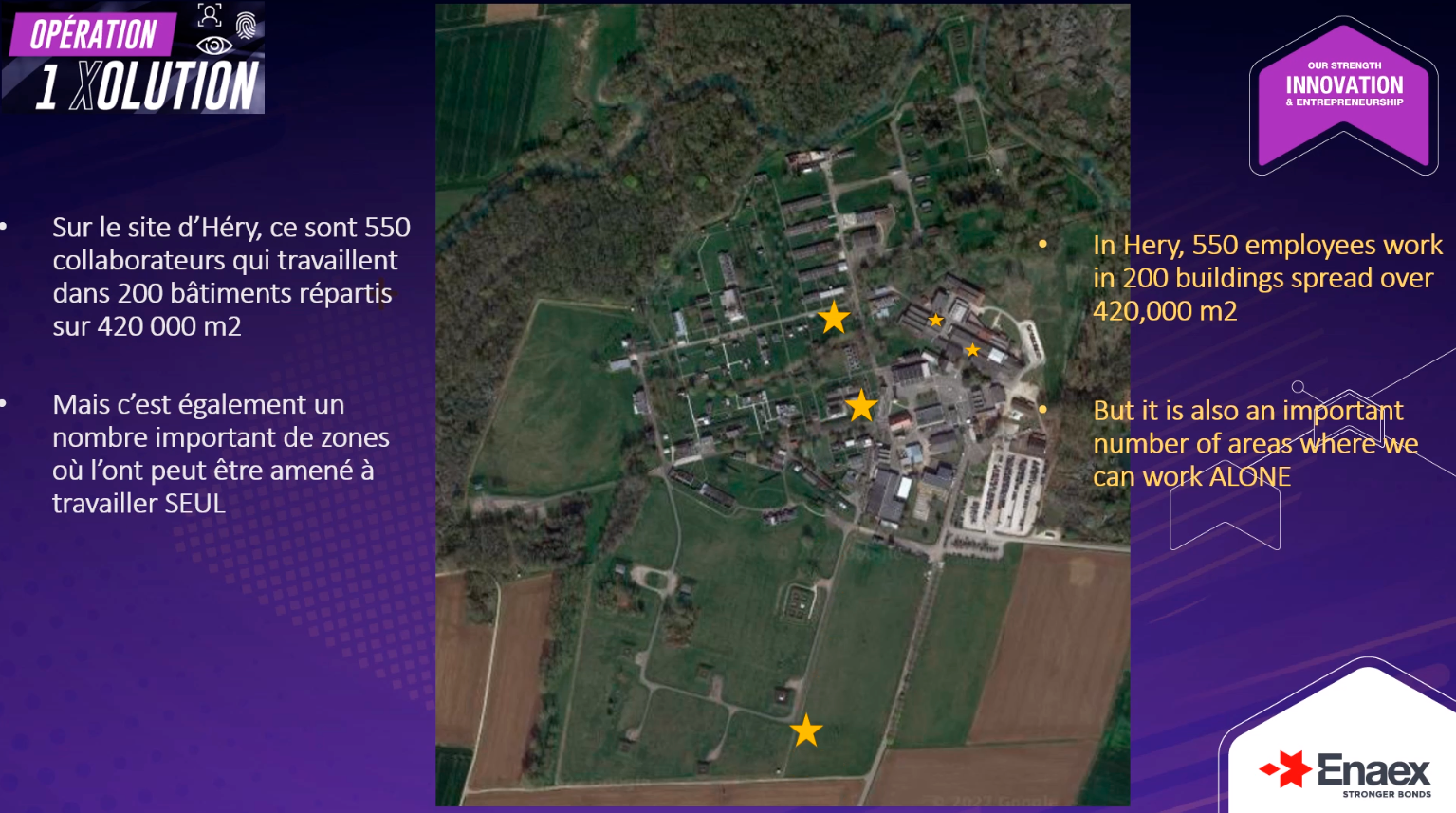

YNBA

Lone worker alarm system

This project proposes an alarm device for isolated workers, which would inform the headquarters of their status and reduce the risk levels of working alone.

Team members:

Bérangere Perrin, Farha Lods, Pierre Burtin, Jean Jacques Bellon, Alexandre Claude, Fréderic Marcos.

Área Refrigeración Prillex

Plant cargo truck transit system

This project proposes a system with signaling traffic lights centralized in an application for the dispatcher and truck operator of the plant. This would allow greater control of traffic and a better handling of emergency situations.

Team members:

Alexis Arredondo, Luis Olivares, Osvaldo Peña, Jorge Canelo, Richard Molina.

Booysendal Safety Innovation

Crane to lift water tanks.

This project identified the resigned problem of removing water tanks from plants by hand, and proposed the use of a crane to lift these tanks, thus removing people from the risk area.

UMK

Electronic scales in product silos

This project proposes the use of electronic weights to eliminate the risk of collaborators climbing up the silos to determine the amount of product present in them.

EMTS Control de Flyrock

Calculation tool to avoid deviations due to faulty blasting

This project identified the resigned problem of rock throwing risk due to faulty blasting and proposes a simple calculation tool to be operated by field personnel in order to estimate the magnitude of the risk and propose to stop the operation if necessary.

Team members:

Raúl Chepillo.

Chuquicamata Subterránea

Operator shift delivery and reception system

This project identified the confusing and informal delivery and reception of truck operator shifts as a problem, so they propose a self-service module in which the outgoing operator describes the safety and operational status of the truck he used to completetly inform the new shift.

Team members:

Jorge Abarca.

Choose your favorite project and help its team win great prizes.

- REMEMBER, YOU CAN ONLY VOTE ONCE.

Projects will be evaluated on the following bases:

Impact/reach: 30%

Innovation: 30%

Teamwork: 20%

Budget: 20%